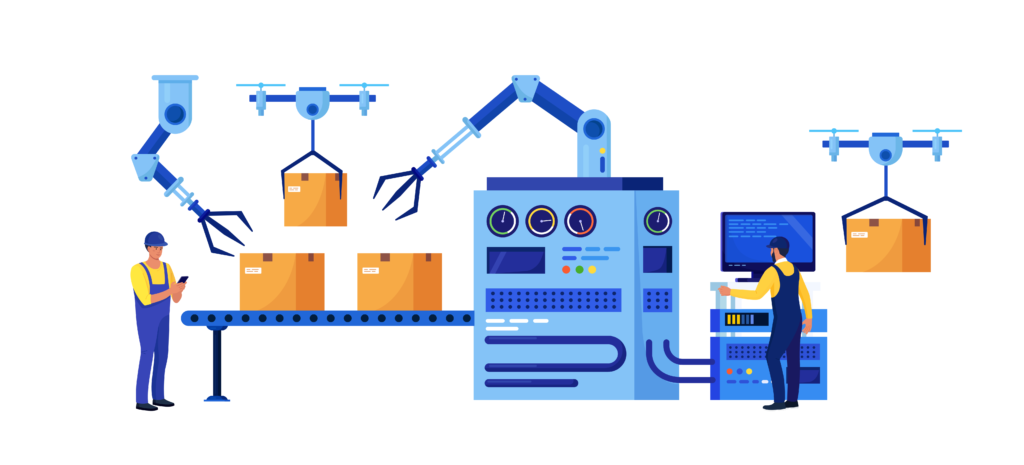

AcceleratingDigitalTransformationinManufacturing&Beyond

KASH Tech – Turning Data into Decisions. Turning Technology into Transformation. Empowering businesses with intelligent data, smart manufacturing, and seamless IT solutions.

Kashtech Products

KASH-T Ally

AI-powered financial analytics with Tally integration

KASH-Trackmate

SMT line traceability & performance analytics

KASH-Quote

Intelligent automated quotation engine

KASH-Line360

Assembly line monitoring & optimization

KASH-Peak

Enterprise-grade data migration & integration platform

IndustrialAssociations

OurServices

Solutions&FocusAreas

Delivering agile, collaborative, scalable, AI- powered and result-oriented solutions to enterprises globally

BarcodeScanning&Labelling

Barcode Scanning & Labelling Systems play a critical role in modern manufacturing by improving traceability, efficiency, and quality control across the entire production cycle. Our systems are designed to integrate seamlessly with your ERP, MES, WMS, and IIoT platforms, giving you total control over inventory, work-in-progress, and finished goods.

IntegratedAccounting

Integrated Accounting solutions connect your financial management with real-time operational data from barcode scanning, inventory, production, purchasing, and sales. By automatically updating stock levels, material consumption, production costs, cost of goods sold, invoicing, and ledger entries with every transaction, the system eliminates manual data entry and reduces errors.

SurfaceMountTechnology

Surface Mount Technology (SMT) is a critical enabler of modern digital manufacturing, allowing electronic components to be mounted directly onto the surface of printed circuit boards (PCBs) with high precision and efficiency.Barcode Scanning & Labelling Systems play a critical role in modern manufacturing by improving traceability, efficiency, and quality control across the entire production cycle. Our systems are designed to integrate seamlessly with your ERP, MES, WMS, and IIoT platforms, giving you total control over inventory, work-in-progress, and finished goods.

InjectionMoldingOptimization

Injection Molding Optimization focuses on improving efficiency, consistency, and cost control across the entire molding process. By analyzing and fine-tuning critical parameters such as temperature, pressure, cycle time, cooling time, material flow, and mold performance, manufacturers can significantly reduce defects, material waste, and machine downtime.

InventoryManagementSystem

Inventory Management System provides complete, real-time control over stock levels, movements, and locations, helping businesses reduce costs and eliminate inefficiencies. By tracking raw materials, work-in-progress, and finished goods through barcode or RFID technology…

ChallengesWeSolve

Unexpected equipment failures can bring production to a halt and drive up operational costs. Our AI-powered predictive maintenance solutions continuously analyze equipment performance, detect anomalies, and forecast potential failures before they occur. This reduces unplanned downtime, improves safety, and extends the lifespan of critical machinery.

Enhance supply chain resilience and efficiency with intelligent forecasting and real-time insights. Our solutions improve inventory management, demand planning, supplier coordination, and logistics routing. This ensures timely deliveries, reduced stockouts, and a more agile manufacturing ecosystem.

Deliver consistent, high-quality products using AI-enhanced quality control systems. Our computer-vision and pattern-recognition technologies detect defects with precision, reduce inspection time, and improve production accuracy. This leads to fewer recalls, higher customer satisfaction, and improved brand reputation.

Cut energy costs and improve sustainability with intelligent monitoring and optimization. Our energy management systems track consumption patterns, detect inefficiencies, and automatically adjust operations for optimal usage. This helps lower utility expenses and supports sustainability goals across the facility.

Achieve greener, more efficient operations with AI-driven sustainability tools. We help manufacturers minimize material waste, monitor environmental impact, and optimize resource consumption. From smart energy usage to waste pattern analysis, our solutions support both cost savings and environmental responsibility.

Empower your workforce with actionable insights derived from real-time production data. Our analytics platforms transform raw factory data into clear dashboards and predictive models, enabling faster, smarter decisions. Identify inefficiencies, optimize workflows, and improve overall operational strategy.

Support and upskill your workforce with advanced digital tools. Our solutions include AR/VR training modules, AI-guided instructions, and intelligent assistance systems that help workers perform complex tasks more effectively. Increase productivity, reduce training time, and promote safer operations.

Transform traditional production lines with smart automation technologies. From robotic process automation to AI-driven machine coordination, we help streamline repetitive tasks, improve throughput, and ensure consistent output quality. Automation reduces human error, increases speed, and enhances overall operational efficiency.

CaseStudy

- All Posts

- manufaturing

Testimonials

KASH Tech played an integral part in converting a subset of our legacy reports into WebFOCUS. They demonstrated their ability to quickly understand our business while working with complex stored procedures and data models. They are always available to help with our BI needs and are timely in responding to our communications. We look forward to continuing our partnership with KASH

Tech in future projects.

We engaged with KASH tech to help us build a new portal for our sales team, a historically "hard to please" user group. Throughout the process, the KASH Tech team was extremely responsive and easy to work with. They took the time to understand the non technical challenges as well as the technical ones. They really learned about our business and what we felt would work and what wouldn't. Our consultants Ben and Hima were creative and thorough and were true partners during the project. The best part is that our Sales team has stopped asking for their old Excel reports back.

When our business users demanded more from our BI platform we reached out to KASH Tech. KASH Tech has been a trusted partner in guiding Steel Technologies to modernize our analytics platform to better serve our business users. They have been extremely responsive to our needs providing insights and hands-on customer service along our journey to transform our data and analytics services. Anyone looking to improve their Bl reporting and data analytics capabilities should contact KASH Tech.

Your privacy is our responsibility

We believe that trust is paramount in a relationship. We do not own or sell your data, and we most certainly do not bank on advertising-based business models. The only way we make money is from the software license fees you pay us.